Starch Wet Milling Process

Corn wet-milling is a process where components of corn kernels are extracted to produce a highly purified product. Most of the products from this process are valuable and mainly required by the food industry. Through this process, every part of the corn is useful to produce the quality ingredients. The characteristics of this process are based on physical separation of components, mostly by weight and size. Water is needed as it is a wet process and it works as separation / carrier agents in washing steps. There is also a pre-soaking process called steeping. The corn is soaked in a sulphur dioxide solution, this aids with this separation process.

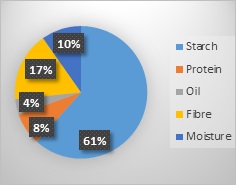

Standard Composition

Starch 62% – Protein 8% – Oil 3.8% – Fibre 17% – Moisture 9.8%

Cleaning

A series of sieves and screening to remove any particles, any foreign matter.

Steeping

Soaking the maize kernel in a sulphur dioxide solution 50 degrees for around 32 hours. This allows the starch granules to separate out cleanly. It also serves as an anti-microbial. At the end of steeping this steeping liquor is protein-rich and can be used as a nutrient for fermentation and animal feed called CSL.

Germ Recovery

As the process step suggest the germ is separated from the other parts of the corn. The separated germ is cleaned, dried and passed through a germ press to extract oil from it. The solid particles remaining after oil extraction is called germ meal. Maize Germ is a good source of amino acids used in animal feeds. The refined Maize corn oil is used for salad oils and cooking oils.

Fibre Recovery

Further separation and grinding. Screens are used to separate the fibre from the mixture. The remaining fibre is called Corn Gluten – Avon Feed around 21% Protein.

Gluten Recovery

The remaining slurry containing just the protein (gluten) and starch is called mill-starch. Water is removed from the mill-starch prior to moving into a separator. Centrifugal forces are applied to separate the starch from the gluten as they differ in density. This Gluten Meal – Avon Gold is around 60% Protein.

Starch Processing

Starch goes through several wash cycles. The supernatants are separated at each washing stage. A very high purity of Native Starch can be recovered by wet milling, the high purity is very important for Corn syrups or Starch to be further modified.

Co-Products Manufacture

Co-Products account for around 34% of the wet-milled yield. In fact 23% of corn that is processed has a very low value.